Dear backers,

As you are well aware, we keep pushing our PCB manufacturers in North America to the limits of what they can do. It seems that their limit was reached 2 weeks ago. We anticipated this limit and figured out a strong plan to get to production ASAP in China. This update is longer than usual so you can get a better grasp on what’s happening behind the scenes.

Check out the plan below.

DEVELOPMENT STATUS

Before I share the plan with you, let me quickly explain our development challenges concerning the printed circuit boards (PCBs):

Those are standard PCBs (not the ones we use). We can’t share images of our own to protect the Intellectual Property of the earbuds.

With this approach in mind, we worked very closely with a couple of North American PCB manufacturers who improved their boards tremendously to fit our needs… until they couldn’t go any further.

The thing is, although they now understand the inner workings of our PCB design, the local manufacturers are limited by the equipment they use. Since more than 90% of all PCB manufacturing is done in Asia (and most of it in China), some of the companies there are able to invest in more sophisticated machinery and get a lot of experience from complex PCBs. They are also able to work with innovative materials that we need to make our PCBs work as intended.

The caveat with Chinese PCB manufacturers is that although they are equipped for that type of production, they start from scratch with us regarding the understanding of how our PCB works and why it is designed this way. The last time we were there, we were disappointed by what they delivered, but we didn’t know at that time that we need to work hand in hand with them during every step of the PCB manufacturing process. They absolutely must understand the inner workings of our PCBs in order to make it work as we expect.

This is why we’re going all in with new manufacturers in Shenzhen, who will become an extension of our team. Here is the plan:

Step 1 – Make a list of potential electronic PCB manufacturers in South China

Our mechanical manufacturer, who is located in Shenzhen, is a rare gem. They are providing many resources and helping us make it work. They don’t do the electronics but they do all the mechanics. He provided his own engineers to visit electronic manufacturers. They actually took a full week of research just for us (we’re not paying them for this by the way, that’s how much they believe in Phazon).

They came up with a list of 15 potential manufacturers. With our CTO’s guidance, they reduced the list to 7 suppliers.

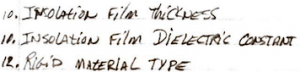

Some of our questions to the manufacturers to assess their skills

Step 2 – Our CTO (Sylvain) needs to meet with the manufacturers so they fully understand the inner workings of our PCBs

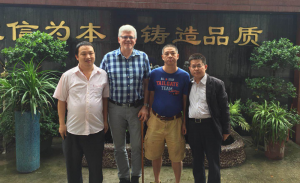

Sylvain left Montreal last Thursday and he started visiting manufacturers as soon as he landed in China. Of the 7 he visited, 3 seemed extraordinary. To make sure communication was fluent, we brought a translator.

Sylvain visiting suppliers

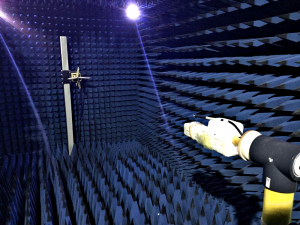

A RF test chamber (to optimize connectivity), located in a supplier’s factory

Step 3 – Test at least 3 different manufacturers simultaneously and see which one is the best

Those suppliers don’t just say that they can do it, they actually provide actionable feedback. Sylvain is currently in the process of making small adjustments on the source files. Those adjustments are based on the manufacturers’ feedback so we could match our design with their manufacturing capabilities. Therefore, it’s a definitive improvement compared to the files sent out to our local manufacturer. Our CTO is 100% sure we’ll succeed with those new suppliers.

Step 4 – Make the pre-production units

If the outcome of step 3 is positive, we’ll do some mechanical adjustments in order to move the needle towards the production units.

Step 5 – Make the production units

Once production has started, the shipping estimate can confidently be given.

Step 6 – Shipping

Hooray!

MANDARIN CLASS

While English is really the dominant business language, people really appreciate when you do the effort to speak their domestic language. Since we want strong relationships with Chinese manufacturers, we believe that learning Mandarin basics will help us build better bridges.

We took a full day of learning to get the basics right.

USER GUIDE

Here’s the first draft of our user guide. We decided to go for more imagery and less text.

The image placeholders will be replaced with outline icons.

Scheduled in the next update:

The next update will provide a lot of info concerning the prototypes and therefore the connectivity associated with.

I’m confident that our CTO proximity with the extremely competent manufacturers we curated, will make wonders.

Chris